Sheet metal is not a homogenous group. The term refers to the format, not to a specific metal. You can find a great variety on the market. Some are more difficult to locate than others are. It may depend upon the rarity of the metal, but the qualities of the metal are a major factor.

As is the case with many substances, some metals prove to be more popular than others are. While many metals or even metal alloys can be stretched into sheets, not all make it onto the shelves of suppliers. In Minneapolis, certain types of metal always remain in high demand. Below is a list of three of the most common.

Cold Rolled Steel (CRS)

CRS is one popular form of sheet metal. It comes out of the foundry in one of two basic types:

1018: This low carbon steel finds favor for its easy formability, machinability and weldability

A366 / 1008:This is a commercial quality steel. Its properties include easy formability, high strength and an excellent surface finish

Overall, CRS, with a more consistent composition than hot rolled steel (HRS), is much easier to machine.

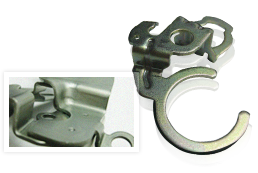

Stainless Steel

This alloy possesses properties that make it popular for a variety of uses. These include:

Outstanding corrosion resistance e.g. 303, 316

High hardness e.g. 410

Good weldability e.g. 301, 304, 316

Formability

Excellent wear e.g. 301

Good machinability e.g. 303

Aluminum

Aluminum comes in various alloys. This material is a favorite among many industries. The properties that they appreciate are:

Excellent corrosion resistance e.g. 5052-H32, 6061-T6, 7075

Easy formability

Good weldability

Good strength e.g. 2024, 6061-T6,7075

Machinability

Lightweight

Sheet Metal

Sheet metal comes in different metals and gauges. Minneapolis suppliers always keep in stock the most common types of metal for their customers. While some clients request rarer metals, others consistently ask for the most common and popular ones – specifically CRS, stainless steel, and aluminum.