If you have ever taken a good look at the moulding in your home, you may have wondered, however briefly, how that beautiful piece of trim was made. Chair railing, baseboards, crown molding all go through a special process using moulding knives to take a rough-cut block of wood and turn it into a gorgeous piece of work.

The process begins when a customer– perhaps yourself– places and order with a moulding knives manufacturer. A design or sketch is drawn up with a range of the widths, from ½ inch wide to over 6 inches wide. A CAD-trained technician then takes the rendering and scans it into a CAD-drawing. The CAD-drawing is sent to the client as a proof to make sure the blade is as desired. If a moulding sample is sent, the manufacturer simply compares the CAD-drawing to the sample for accuracy.

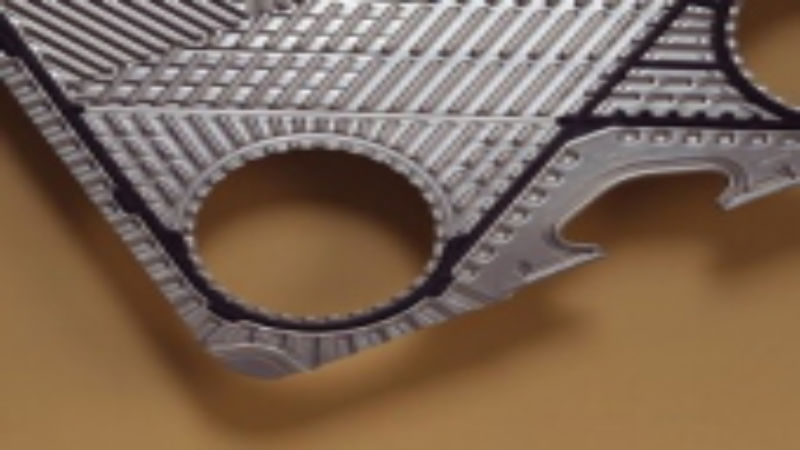

Once the CAD-drawing is verified for accuracy, the drawing is forwarded to the knife manufacturing facility where it is computer cut out of carbide steel and any additional relief in the blade is hand ground in behind the cutting edge. It is the perfect marriage of modern technology and old-school craftsmanship. Almost any edge and design can be created, from the very simple to the ultra-complex.

Once the moulding knives are cut, they are sent back to for additional proofing by the guys who drew up the blade. If the blades pass their thorough inspection, they are wrapped in foam and boxed up and shipped to the client who placed the order.

If you are interested in having high quality moulding knives made, you have two options to place your order. Send to the manufacturer a sample or drawing of what you want made. If you are trying to match an existing cut, it is better to send in an actual sample so that they can precisely match up the cut and relief of the blade. Make sure to specify the width of your blade and whether you want steel or carbide.

The cost between the two metals is quite different. For steel, you should expect to spend approximately $30 to $40 per inch, whereas the carbide you can spend upwards of $80 per inch. That price should cover all labor and materials, from scanning and drawing to cutting the actual blade, gib and balancing it.

Moulding knives are a true engineering feat and have made the lives of woodworkers and craftsmen. Hot Knives offers all kinds of high-quality shaper knives and moulding knives.