The manufacturing of parts and components made of metals, alloys, and even new options in plastics and resins is very different than it was even a couple of decades ago. Today, most parts are made on CNC machining equipment, which allows for precision control of the manufacturing process to allow for tight tolerances and virtually identical parts and components even with millions produced over years of production.

One of the most commonly used machining options in the formation of large and small parts and components is CNC milling. All CNC milling services use computer numerical control of the cutting tool and the system, which provides for absolute precision with each part produced.

Understanding the benefits of CNC milling services is helpful to an OEM in recognizing when this type of machining option is the best one for the production of specific types of parts and components.

The Basics

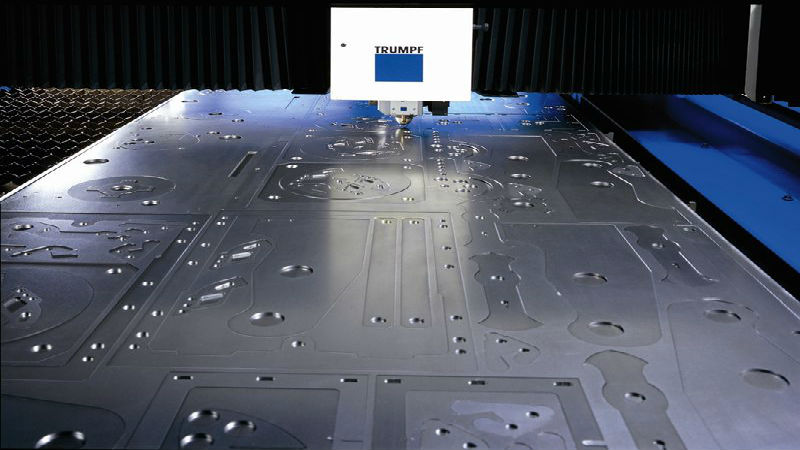

All CNC milling services start with a solid workpiece and then, through the use of a cutting tool, remove selective areas to create the desired final shape. Different options in milling machines offer movement along different axes, which allows for complex shapes to be formed in a single machine.

A CNC milling machine can be designed as either a vertical or a horizontal machine, and the two options allow for different sizes and configurations of parts and components to be formed on the equipment. Horizontal milling machines are typically three or four axis machines, while vertical machines can have three to five axis movement.

The vertical milling machines have a table to hold the metal, and the spindle is vertically set in relation to the table and the workpiece. With the horizontal machine, the spindle is positioned horizontally, which allows for the formation of parts from longer and larger workpieces.