Pipe fittings work to connect and orient pipe lengths and assemblies for proper flow. Stainless steel manufacturing ensures temperature adaptability and corrosion resistance that keeps contents pure.

Purpose of Pipe Fittings

Stainless steel pipe fittings serve multiple purposes in a system, including changes in pipe sizes or directions, tees, outlets or taps. Pipe fittings help a system adapt to its function.

Benefits of Stainless Steel Fittings

Aside from their ability to meet codes and standards and their durability and long-life, these fittings also offer other benefits:

Material That’s Easy to Work

Easy work-ability is a plus on a construction site or project. In addition to other unique attributes, stainless steel pipe fittings can customize easily in manufacturing, which allows for a shorter turnaround.

Corrosion and Temperature

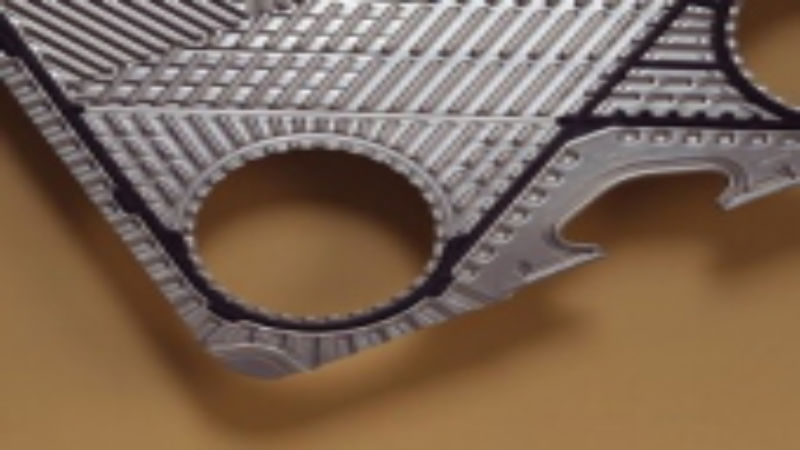

As the name implies, stainless steel has a high level of corrosion resistance. Fittings made with stainless steel also have a passivation layer, inside and outside, that quickly heals and protects against corrosion in scratches. Corrosion resistance is important in systems that work with food or beverages.

Varying stainless steel grades also adapt well to low and high temperatures, making it ideal for systems that operate in extremes.

An Ideal Application

Stainless steel pipe fittings have unique properties that make them useful for various applications. Their durability, workability, corrosion resistance and temperature adaptability make these fittings ideal for systems that see temperature extremes and high humidity. Their malleability allows for short turnarounds, and their corrosion resistance makes them ideal for food-service and medical applications.