Ever month, the market is flooded with another 1,500 new beverages. They are quickly tasted and, in many cases, forgotten, as the public moves on to find the next novel flavor or experience. The public can be fickle in their taste. To meet and even overcome this challenge you need to rely on the best beverage processing equipment possible.

Producing the Goods

It does not matter whether you are producing beverages using soy, fruits, coffee, tea or vegetables; the processing equipment you use is significant in achieving production goals. To produce the beverages you require in the amount and quality demanded, automation seems the ideal way to go. However, certain challenges govern this route to improved productivity.

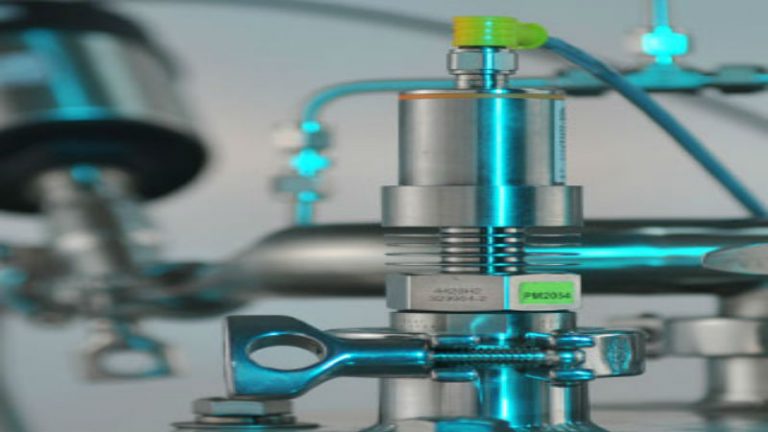

The equipment that makes up a beverage processing system includes:

- Mixers and blenders

- Centrifuges

- Pumps

- Motors

- Air compressors

- Carbonators

- Conveyors

The entire process does not occur in a single stage, it also occurs under less than ideal conditions.

Automating the Beverage Processing System

Automation is continuing to grow in the industry and has since 2012. The reasons are simple but cost-effective. Automation can accomplish a number of things including:

- Reducing manufacturing costs

- Improving beverage quality

- Increases flexibility by providing quick turn-around of various aspects including ingredient changes and additions

- Improves bottling efficiency through the addition of software and monitoring devices

- Improved beverage safety and purity

- Decrease turn-over and wait times

All are reasons why the industry is increasingly turning to automation and computer systems to help run, control, monitor and rejuvenate their beverage processing systems. It will remain to the manufacturer to decide whether to employ a centralized or decentralized system of automation. Both have their advantages and disadvantages. Within the food & beverage industry, the secret to discovering the best system – centralized or decentralized, can only be arrived at through a thorough analysis of each individual component of the beverage processing equipment system.

Automating Beverage Processing Equipment

For a beverage processing plant to reach its full potential, it needs to automate fully. Stringent health and safety standards, the need for increased efficiency and the ability to improve monitoring of all types are reasons for automation. One issue that has held back full automation until recently has been the lack of systems robust enough to handle the adverse environment of processing systems. This has changed over the past few years. With better technology arriving on the market, it is now possible to for automated beverage processing equipment to deliver the goods to both your customers and shareholders.