Aluminum is a versatile metal and can be used in many different ways. It can be used to make cars, boats, house siding, and more.

Extruded aluminum shapes are the most common in the industry. They are used in various industries such as construction, architecture, and transportation.

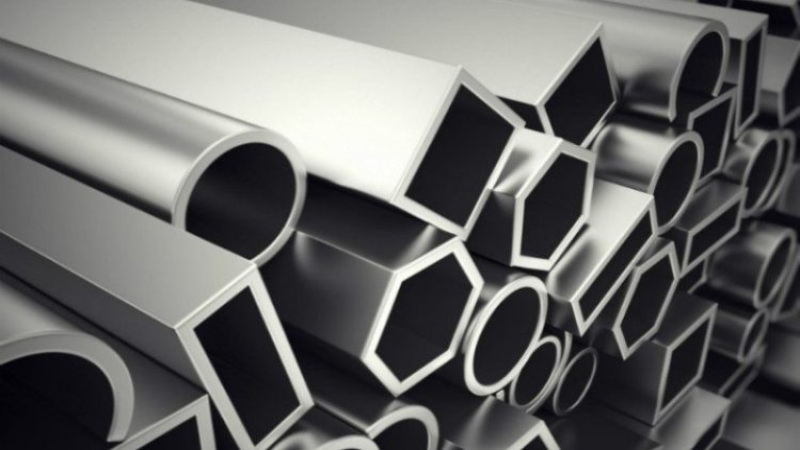

Types of Aluminum Extrusions

There are many types of extruded aluminum shapes that can be used for different purposes. The most common type is a channel shape, which is usually used to create an edge or a barrier that can be attached to another object or surface.

Different types of extruded aluminum shapes have different properties and use. For example, there are several types of channels that have different heights and widths which makes them applicable for various purposes such as a handrail or guardrail system.

Process For Shaping Metal

Aluminum extrusions are made by extruding molten aluminum through a die in a process called drawing. The die at the end of the extrusion line determines the final shape and size of the aluminum shape.

Benefits of Using Custom Aluminum Extrusion

The perfect extruded aluminum shape is a precision metal shaping service that has many benefits, such as:

- It is durable

- It is cost-effective because it can be reused and recycled

- It can be customized to suit your needs.

Conclusion

Custom metal shapes offer designers flexibility in form and function because they can be designed to meet specific requirements for weight, strength, corrosion resistance, appearance, or other properties such as weldability or machinability.