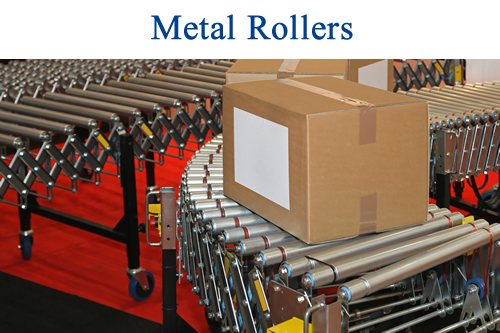

Having the right type of conveyor and suitable industrial rollers is integral to your business. A big part of choosing the right parts comes from understanding the requirements of the products you’re moving. Here are a few specifics to consider when choosing the best type of conveyor belt system for your operations.

Product Size

First and foremost, think about what size system you’ll require. Are you producing uniform-sized products? Or will you be manufacturing a variety of sizes and shapes? Conveyors and industrial rollers come in a variety of different materials to choose from to best suit your products and production rate. This is why it’s best to choose custom construction for your conveyor, says Conveyor Systems and Engineering Inc.

Product Type

Carefully consider the type of product that you’re moving. Different types of products require different specifications, whether they’re corrosive items, chemicals, or food, to name a few. For example, if you are manufacturing food products, you need to make sure that your conveyor and all related aspects of your building and design are USDA/FDA approved. You’ll also need to choose rollers and materials that can be easily taken apart for thorough cleaning and sanitation.

Production Speed

A good conveyor belt will mean nothing if it’s not helping your production stay up to par. You’ll need to choose a conveyor that can run at speed matching your production rate. Make sure that you also consider any transfers that you’ll need between conveyor systems and choose the most effective method, whether that’s a dead plate or a gravity roller.

These are just a few guidelines for configuring your conveyor system. Without doing the proper research and choosing the right types of rollers and parts, you run the risk of having your product and production negatively affected by a poorly planned system.