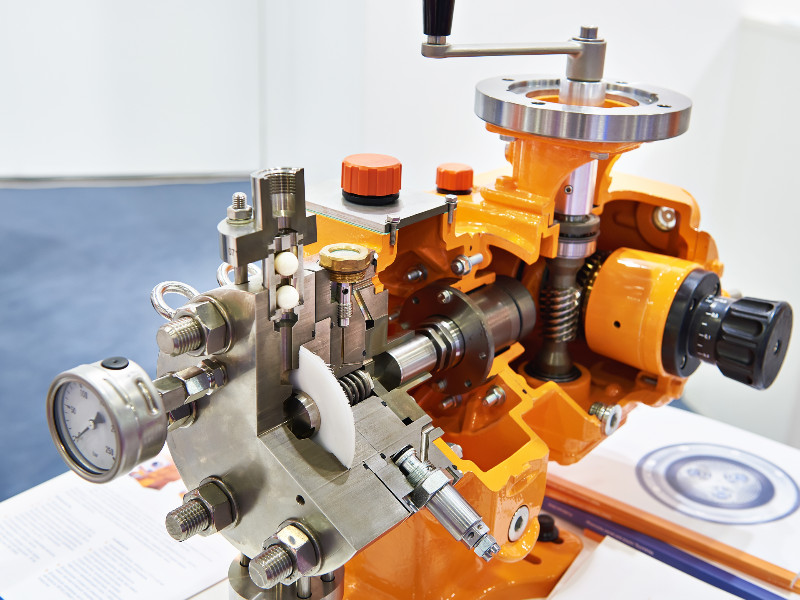

In the pharmaceutical industry, manufacturing products often require delicate and complex methods. To improve productivity and efficacy in production, one of the most effective ways to streamline this is to have a superior quality pharmaceutical mixer.

As mixing and blending are essential in a pharmaceutical company, an array of mixers is used to get the desired result. Laboratory mixer, batch mixer, high-speed mixer, mass mixer, blender mixer and communiting mill are the different types. Now, what are the benefits of using a mixer? Let us find out!

What are the perks of using a mixer?

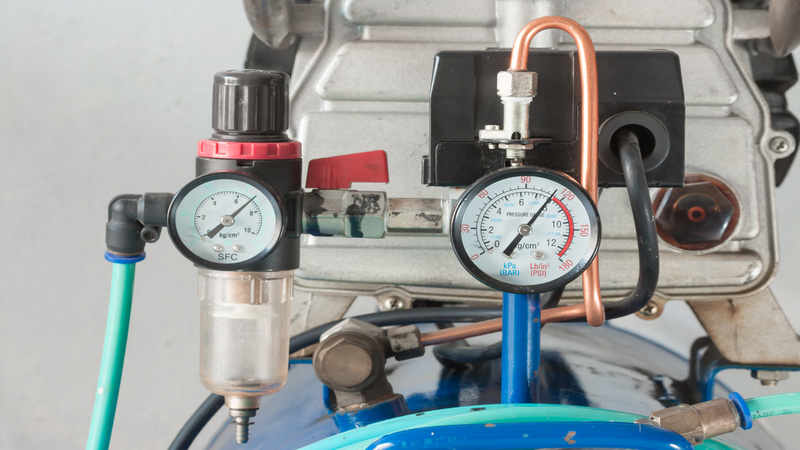

• High cleanliness standard- While manufacturing a pharmaceutical product, sanitation and cleanliness are the prime concern. Hence, using a pharmaceutical mixer is essential because it is designed for laboratory use. The device is sealed, reducing the risk of contamination and leakages.

• Thorough mixing- The products are thoroughly mixed so that the latter steps can be initiated. When you use a quality laboratory mixture, you can rest assured that the powder/solution/granules can be meticulously mixed. There are different categories of mixers with varying motor speeds- choose one that can help you with the product that you want to produce.

• Improved efficiency- Manufacturers are always looking for options that can boost their efficiency during operations. You save a lot of time in the mixing step, thus, saving a lot of time in the manufacturing process. In short, time is saved, the operation is improved and the company runs in profit.

Pharmaceutical mixer delivers top-quality performance, eliminating all your concerns regarding safety and product output. The benefits further show that why you need one. However, choosing the right mixer is important to get the optimal result. As there are different models available in the market, it is wise to understand the features and select the one best suited for your factory’s application.