Large aluminum producers take raw materials to create the specific aluminum qualities required for a specific type of aluminum or for specialized requirements. Aluminum extruders handle this process to create the bar, plate or sheet aluminum required.

This is a very specific process which requires experience, skill and the ability to process the raw materials. The large aluminum extruders then sell either to a metal service center or to the end user or client. Typically the end user will still need the services of a metal service center to handle precision cutting of the aluminum. This is particularly true for large orders where hundreds or thousands of parts have to be cut to exacting standards.

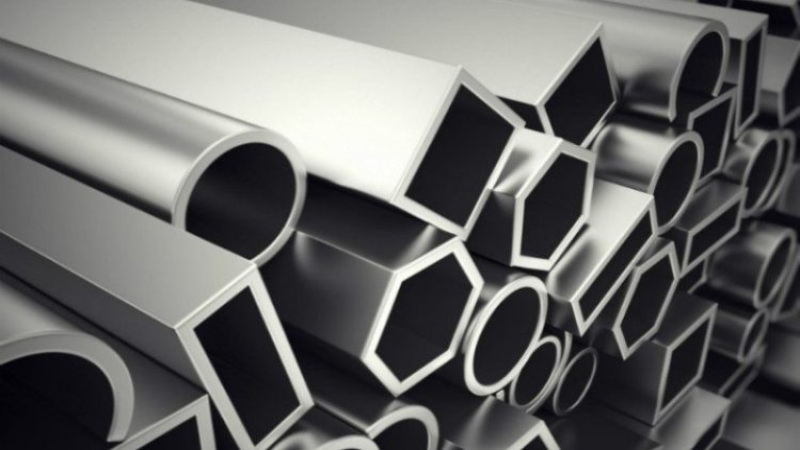

The Extrusion Process

The large or small scale aluminum extruders all use the same general processes. It starts by setting up a system for extrusion which allows for tight control over the specifications of the end product, which will be plate, bar or specialized shape. Plate can then be further processed to create aluminum sheeting and then the very fine aluminum foil used in many different industries, including the aerospace industry.

To get started a large billet of aluminum alloy, which may also be called an ingot, is preheated in a large furnace. This billet can weigh in excess of 20 tons with some of the large international aluminum extruders processing systems.

Heated in excess of 700 degrees Fahrenheit, which will depend on the alloy, pressure is then applied through a press ram to force the softer metal of the billet into an extrusion press containing a die. This die determines the shape of the extruded aluminum which will be formed.

Since the aluminum is soft enough to flow through the die, it forms a perfect and complete mold of the die. The pressure continues to force the formed aluminum out and onto a stretcher, where tension is removed from the form. Finally, the formed aluminum bar, plate or shape is cut and then aged to increase strength and corrosion resistance.

Considerations

Working with a metal supplier working with the top aluminum extruders is always an important consideration. With expert aluminum production and tolerances to specifications, you know the aluminum you order will always be top quality.

In addition to working with the best aluminum extruders, selecting a top aluminum service company to complete precision cutting and shipping is also critical. This combination will always result in the best quality materials on the market.

At Howard Precision Metals we only do business with the best aluminum extruders in the world. To learn more about our suppliers see us at Howardprecision.com.